We make our signs with white pine boards that we purchase from local lumber yards.

All of the boards are kiln dried, and we carefully select only sections of the boards that are free of knots. We try our best to avoid pieces that will warp, split or bleed sap. This is one of our greatest challenges.

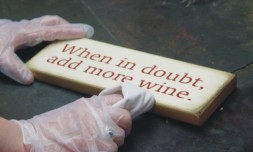

There are over ten steps involved in making the signs. After we bring the boards back to the shop, we have to select the usable pieces, cut them to length, rip them to width, rout the key-slot in the back, paint them, print them, belt sand them, hand sand them, apply an antique wash to them, apply a finish to the edges, and finally wrap them in newsprint.

Our process is indeed labor intensive. We do use power tools for the woodworking, but the rest of the steps are done entirely by hand.

If any sign should ever warp, split or bleed sap, please let us know and we'll happily replace it with a new one. We try our best to use only quality pieces, but wood is subject to change, especially with all the temperature and humidity fluctuations that occur throughout the year. It's still a better choice than pressboard.

OX POND PRESS

Nostalgic Wooden Signs - Made in N.H.

View from our shop.